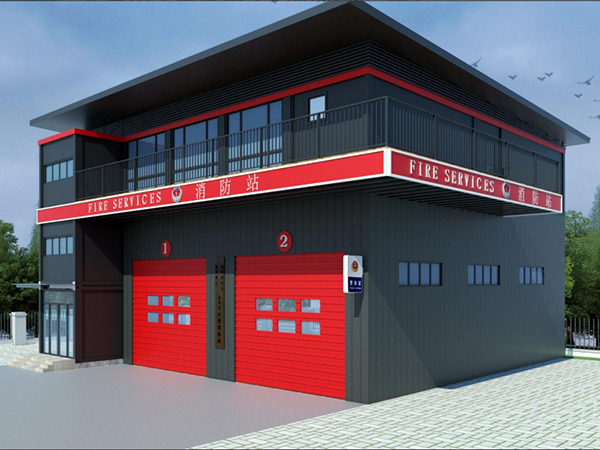

Prefabricated House for Fire Station

The modular fire station is based on an independent box structure as a unit module, which is composed of a structural system, a wall system, a strong and weak current system, and a water supply and drainage system.

The main building of this project adopts the form of integrated modular house construction, which can be quickly installed on site, reducing on-site operations and shortening the construction period; quickly realize the overall function of the building, and realize the green environmental protection concept of “zero” construction waste on site.

The overall cooling and heating methods of the building are mainly air-conditioning and electric heating. All railings comply with safety regulations, and the height is not less than 1.2 meters. The overall building functions meet the functions of duty, preparation, meeting, living, living and other functions, and are designed according to the standard of 15 full-load living. Two steel structure garages can be used for two fire trucks, and a single garage is designed to be 12 meters long and 6 meters wide. The fire garage door adopts electric lift door, 4 meters wide and 4.5 meters high. The ground bearing capacity of the garage is more than 30 tons.

Product details

| Construction Time | 2018 | Project Location | Beijing, China |

| Number Af Modules | 239 | Area Of Structure | 5052㎡ |

Brand: Homagic

Place of Origin: Shenzhen, Shanghai

Advantages: Various scales, complete functions, energy saving, environmental protection, sound insulation, fast installation and others.

Application: Traffic congestion points, densely populated points, and weak links in towns and villages

Design Concept: The integration of construction, decoration and use, aiming at saving early, destroying small and quickly arriving at the scene to fight the initial fire, to make up for the shortage of the number of existing fire stations and the fire-extinguishing capacity of micro-fire stations, to meet the requirements of quick dispatch of the fire brigade, and at the same time Fire preparedness and fire safety publicity and other functions. Improve the rescue efficiency of firefighters and provide more comfortable logistical support conditions.

Finished product display - internal and external structure

Video-Production process monitoring

Video-Completion of acceptance

Customized Product Process

Professional Design Ability

Our company develops a BIM collaboration platform based on "enterprise cloud", and the design is completed on the platform with "all staff, all majors, and the whole process". The construction process is carried out on our "fabricated intelligent construction platform" with independent intellectual property rights. The platform can realize the joint participation and collaborative management of all parties involved in the construction. Fully meet the "intelligent project management platform" requirements of integrated buildings. Completed the development of "Box House Design Generation Toolset Software" and obtained three software copyrights. The software functions are comprehensive and have high operating efficiency, including "4+1" main functions and 15 special functions. Through the software application, the difficulties of collaborative work in the links of design, production, order dismantling, and logistics have been solved, and the overall implementation efficiency and cross-departmental collaboration efficiency of the box-type housing project have been effectively improved.

The material database is established through the BIM model, combined with the comprehensive management platform, the material procurement plan is formulated according to the construction process and the progress of the project plan, and the material consumption types at each stage of the construction are quickly and accurately extracted, and the basic data support of the BIM model is used as the material procurement and management. Control basis. Material procurement, management and real-name management of workers are realized through the China Construction Cloud Construction online shopping and centralized procurement platform.

Manufacturing Capacity

Light steel structure products are prefabricated in advance, speeding up the production cycle, helping you to undertake projects faster and complete house construction.

It is a form of using advanced and applicable technology, craftsmanship and equipment to pre-manufacture various components of the building by professional factories before construction, and then transport them to the construction site for assembly. Repeated mass production in the factory is conducive to speeding up the construction progress, shortening the construction period, improving the efficiency and quality of the production of components, simplifying the construction site, and achieving civilized construction.

Packaging and Shipping

Inland Delivery

The product specifications and packaging specifications all meet the international container size requirements, and long-distance transportation is very convenient.

Delivery By Sea

The modular prefabricated integrated container house product itself has standard size requirements for shipping containers. Local transportation: In order to save transportation costs, the delivery of modular box-type mobile homes can also be packaged with a standard 20' container size. When hoisting on-site, use a forklift with a size of 85mm*260mm, and a single package can be used with a forklift shovel. For transportation, four connected into a standard 20' container must be ceiling loaded and unloaded.

All In One Package

One flat pack container house consists of one roof, one floor, four corner posts, all wall panels including doors & windows panels, and all components associated in the room, which are prefabricated, packed and shipped out together and makes up one container house. For multiple components, increase the number as required.

Professional Transport

All accessories will be shipped in containers and the main frame will be shipped by sea. Shipping information includes regular product information, testing information required by customer orders, etc. Please consult customer service staff for details.