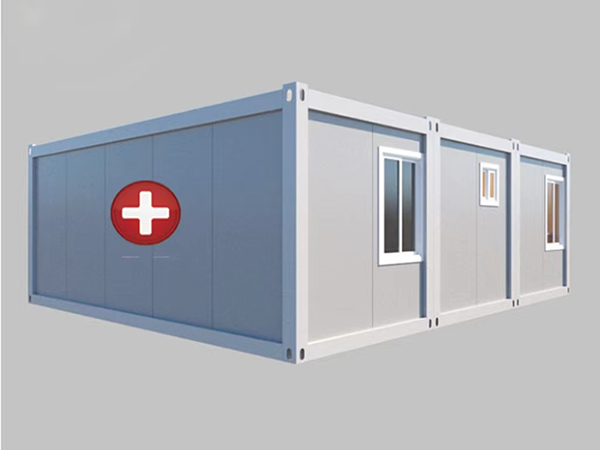

Emergency Hospital Container Prefabricated Modular Space

Prefabricated Modular Flat Pack Container Hospital Container for Emergency Rescue Isolation 0201

HOMAGIC Modular Container Hospital is for emergency treatment and care of ill patients and it can used as isolation ward during the epidemic,which container is combined by several flat pack container house,they can be customized to be any size or configuration. We work with you to create a design and layout that is convenient and accessible with the space required for effective treatments to be administered. Units are secure, simple and clean. It offers more flexibility and customizability than traditional builds. Start treating patients faster. Patient rooms, exam rooms, labs, nurses areas, offices and specialized treatment areas can all be custom designed to suit your needs.

Product details

Single Emergency Hospital Container Information

* Wind resistance: Grade 11(wind speed≤111.5km/h)

* Earthquake resistance: Grade 7

* Fire proof: B2 grade

| Size | 5800mm(L)*2200mm(W)*2800mm(H) |

| Storey | Less than 3 storey |

| Frame Structure | 2.3-4.0mm |

| Bolts | Galvanized Steel Galvanized M12 High-Strength Bolts |

| Surface Finishing | Baked Coating |

| Material for Wall | EPS/Rock Wool/Glass Wool Sandwich Panel |

| Material for Roof | EPS/Rock Wool/Glass Wool Sandwich Panel |

| Material for Floor | 15mm MGO Board with PVC Floor Leather |

| Door | Sandwich Panel Door with Handle and Lock |

| Window | Plastic Steel Double Glass Window with Security Bar |

| Wall/Roof Skirting | Hard PVC Sheet |

| Light | LED Ceiling Light |

| Socket | Universal Socket, Water Proof Socker, A/C Socket, for Your Country Standard |

| Switch | 1-way-switch |

| Distribution Box | On Ceiling for Lights |

| Stairs | Steel Stairs with High-Class Hand Rail |

| Awning | Sandwich Panel Awning |

| Walkway+Balustrade+Awning | Galvanized Steel |

| Sanitary ware and cookware | We supply with extra cost |

Product Structure

| S.N | Component |

| 1 | Roof Corner |

| 2 | Top Beam |

| 3 | Column |

| 4 | Color Steel Roof Tile |

| 5 | Glass Fiber Insulation Cotton |

| 6 | Roof Purlin |

| 7 | Color Steel Ceiling Plate |

| 8 | Floor Purlin |

| 9 | Glass Fiber Insulation Cotton |

| 10 | Cement Plate |

| 11 | Bottom Sealing Steel Plate |

| 12 | Rubber Floor |

| 13 | Ground Corner |

| 14 | Bottom Beam |

| 15 | Wall Plate |

The main structure adopts cold-formed thin-walled profiles; The integrated top frame and bottom frame are connected to the column by bolts to form a box unit; The enclosure system is a 75mm metal sandwich panel; Modular units can be shipped in packs or full cases.

Product Details

Video

Installation Process

Product Advangtage

1) All steel fabric parts and the size of the prefab house can be made according to clients' requirements.

2) The prefab house is low cost, durable structure, convenient relocation, and environmental protection.

3) The prefab house material is light and easy to install. one 50 square meter house five workers 1-3days finished installation, saving workforce and time.

4) All the materials of prefab houses can cycle-use, Meeting the requirements of environmental protection in the world. Special is in the large-scale house projects in the developed region.

5) We used the high-quality galvanized sheets and foam as the materials for the wall and roof.So the prefab house is suitable for fireproofing, waterproofing, etc.

6) Support frame system of steel prefab house: Q235B China standard steel structural. Square tube, Channel steel, etc.

Professional Design Ability

Our company develops a BIM collaboration platform based on "enterprise cloud", and the design is completed on the platform with "all staff, all majors, and the whole process". The construction process is carried out on our "fabricated intelligent construction platform" with independent intellectual property rights. The platform can realize the joint participation and collaborative management of all parties involved in the construction. Fully meet the "intelligent project management platform" requirements of integrated buildings. Completed the development of "Box House Design Generation Toolset Software" and obtained three software copyrights. The software functions are comprehensive and have high operating efficiency, including "4+1" main functions and 15 special functions. Through the software application, the difficulties of collaborative work in the links of design, production, order dismantling, and logistics have been solved, and the overall implementation efficiency and cross-departmental collaboration efficiency of the box-type housing project have been effectively improved.

The material database is established through the BIM model, combined with the comprehensive management platform, the material procurement plan is formulated according to the construction process and the progress of the project plan, and the material consumption types at each stage of the construction are quickly and accurately extracted, and the basic data support of the BIM model is used as the material procurement and management. Control basis. Material procurement, management and real-name management of workers are realized through the China Construction Cloud Construction online shopping and centralized procurement platform.

Manufacturing Capacity

Light steel structure products are prefabricated in advance, speeding up the production cycle, helping you to undertake projects faster and complete house construction.

It is a form of using advanced and applicable technology, craftsmanship and equipment to pre-manufacture various components of the building by professional factories before construction, and then transport them to the construction site for assembly. Repeated mass production in the factory is conducive to speeding up the construction progress, shortening the construction period, improving the efficiency and quality of the production of components, simplifying the construction site, and achieving civilized construction.

Packaging and Shipping

Inland Delivery

The product specifications and packaging specifications all meet the international container size requirements, and long-distance transportation is very convenient.

Delivery By Sea

The modular prefabricated integrated container house product itself has standard size requirements for shipping containers. Local transportation: In order to save transportation costs, the delivery of modular box-type mobile homes can also be packaged with a standard 20' container size. When hoisting on-site, use a forklift with a size of 85mm*260mm, and a single package can be used with a forklift shovel. For transportation, four connected into a standard 20' container must be ceiling loaded and unloaded.

All In One Package

One flat pack container house consists of one roof, one floor, four corner posts, all wall panels including doors & windows panels, and all components associated in the room, which are prefabricated, packed and shipped out together and makes up one container house. For multiple components, increase the number as required.

Professional Transport

All accessories will be shipped in containers and the main frame will be shipped by sea. Shipping information includes regular product information, testing information required by customer orders, etc. Please consult customer service staff for details.